A countdown for Phoenix, Arizona, started in Charlotte, North Carolina when Honeywell made the decision to significantly boost the availability of personal protection equipment for first responders and healthcare professionals in America. At the time, Phoenix city staff didn’t know about the agility test it was about to face.

A countdown for Phoenix, Arizona, started in Charlotte, North Carolina when Honeywell made the decision to significantly boost the availability of personal protection equipment for first responders and healthcare professionals in America. At the time, Phoenix city staff didn’t know about the agility test it was about to face.

“We have moved quickly to expand our production capacity for N-95 masks globally and are pleased to announce our second new U.S. manufacturing line to supply the Strategic National Stockpile,” said Darius Adamczyk, Honeywell chairman and chief executive officer at the White House on March 30, 2020, while announcing the new Phoenix, Arizona, production facility.

At the dawn of the pandemic, before most of America recognized the extent of what it would face, Honeywell was preparing to start-up two new manufacturing locations, including one in Phoenix, that would produce more than 20 million critical N-95 facemasks per month.

“Phoenix has been called upon before to manufacture life-saving products for our country,” said Phoenix Mayor Kate Gallego. “We have an exceptional manufacturing workforce. Our history makes Phoenix attractive for manufacturing expansion. It is quite a story of cooperation between the city and Honeywell to open its manufacturing line in record time. Dedication and commitment by the city staff and Honeywell made it possible.”

For the fourth time in a century, a Honeywell manufacturing facility near Phoenix Sky Harbor International Airport will save American lives. First constructed in 1942, World War II aircraft engines for outmaneuvering enemy planes were designed and built. As the Korean Conflict ramped up in the early 1950s, the operations were moved onto what is now the Phoenix Sky Harbor International Aerospace Corridor and continued to build and design aircraft engines well into the Cold War.

“Honeywell looked across its U.S. portfolio to identify locations where we had space available, could hire quickly and where the local government would support getting the new line up and running as fast as possible. Phoenix and the State of Arizona hit the mark in each of these areas,” said John Waldron, president and CEO of Honeywell Safety and Productivity Solutions.

Now part of the aggressive schedule counting down to mask production, Phoenix Community and Economic Development Director Christine Mackay and Planning and Development Director Alan Stephenson put into motion the steps to make it possible for Honeywell to go from decision to production in five weeks.

“Honeywell now owned this former manufacturing building on the Sky Harbor International Aerospace Campus. They used it for a warehouse,” said Christine Mackay, director, Phoenix Community and Economic Development. “Phoenix inspectors determined Honeywell could adapt the building for manufacturing personal protection equipment.”

Phoenix staff learned that other companies were facing delays trying to obtain permits in cities around the country to manufacture critically-needed personal protection equipment. A city cross-department team was assembled to deliver the Phoenix permits and approvals for Honeywell on an urgent timeline.

“Speed matters when it comes to saving lives,” said Mayor Gallego. “From the beginning, we knew that we were facing challenges getting Honeywell’s facility up and running. We put all hands on deck to get the job done well and done fast.”

Over the past few years, the Phoenix Mayor and Council have approved new inspection and permitting programs designed to slash review and permit issuing timelines.

“Phoenix Planning and Development Department staff was able to help this project be up and manufacturing N95 masks in five weeks,” said Stephenson. “Using a combination of available tools, we were able to work day-to-day with Honeywell as it converted the warehouse to manufacturing. This system allowed us to accommodate in-progress a plan to nearly double manufacturing lines to meet the rapidly increasing demands for masks.”

Phoenix’s ability to pivot in response to Honeywell’s needs helps meet the national demand to get masks and to first responders and healthcare workers.

“The City of Phoenix immediately jumped into action to help us get this production line ready ahead of schedule,” said Waldron. “The city dedicated a team to this effort to get certifications, permits, planning and walk-throughs done as quickly as possible – often in less than 24 hours. Converting a warehouse used for storage into a world-class production site takes a huge amount of teamwork, and the City of Phoenix was a critical partner helping Honeywell produce this much-needed protective equipment.”

Before the clock started ticking, Phoenix sent inspectors into the former manufacturing facility at the Honeywell Aerospace Campus, which was being used as a warehouse. The inspectors noted improvements that would be needed to convert it into a modern manufacturing center, while at the same time becoming familiar with the facility and the Honeywell team. The city team worked with Honeywell engineers to get the new facilities expanded and open without challenging delays.

Phoenix’s speed-to-market development toolbox includes the Annual Facilities Program. This administrative system allows building inspectors to become familiar with a building before permits are requested. A company can proceed with a long list of improvements within an existing building without obtaining conventional building permits under this system.

While this effort covered some of the process, Honeywell was able to expand using other permit expediting tools Phoenix offers commercial construction: Electronic plan review, Permit-by-Inspection, and finalizing plan review in the field.

“This was a defining moment for the city,” said Mayor Gallego. “We had to use every tool we’ve put into the toolbox to help Honeywell scale up fast. When Honeywell told us they were going to save lives with masks made in Phoenix, we opened the entire toolbox to get their facility open.”

The Phoenix development toolbox includes options for commercial buildings unique to large cities. For Honeywell, the team worked to get the building open to make the masks and protect the health and safety of the facility workers.

“We have a very knowledgeable and experienced staff,” said Stephenson. “They knew how best to combine the different construction review tools into one process to meet Honeywell’s needs, just as we do for anyone from the public.”

Stephenson said that with Phoenix being America’s fastest-growing city, the department staff has the breadth of professional experience and teamwork spirit to get critical projects, such as Honeywell, to the finish line that is unrivaled in other big cities.

“When fully ramped up, the Phoenix facility will produce 10 million N95 masks per month,” Waldron said. “When we announced the creation of this facility on March 30 we anticipated the first masks would be produced in mid-May. We were thrilled to see the first masks rolling off the line on April 30. The speed at which we opened this production line is a testament to the hard work and ingenuity of our employees.”

Speed-to-market is important for any major construction project, but for Honeywell, it means saving lives to get the N-95 masks off the line and into the hands of first responders and healthcare professionals. Chris Camacho, president and CEO of the Greater Phoenix Economic Council, stresses how this market pivots quickly as an attraction to the major companies planting flags in the Valley.

“Honeywell’s ability to quickly pivot and stand up manufacturing operations to produce critical personal protection equipment at scale is indicative of the spirit of Greater Phoenix and emblematic of collaboration to entice new businesses to the area,” said Camacho. “Amazon, ThredUP, USAA and Stitch Fix are examples of businesses that selected Greater Phoenix for its ability to enhance speed to market and support business operations.”

Although Phoenix is built on a pioneer spirit turning the desert into a modern city, Camacho notes it is the youngest of America’s largest cities.

“We just roll up our sleeves and get things done,” said Mackay. “Just as Honeywell expressed appreciation with the city’s speed, other businesses, large and small, have taken advantage of these same tools to get open faster than is possible in many other cities.”

Still maintaining quality and delivering service, Phoenix acted at speed for Honeywell’s life-saving product. It is the same “we can do this” attitude that prevails for a multitude of projects.

“This is just what we do,” said Mayor Gallego. “We have a rich history of stepping up when America needs us. That tradition of helping is just another opportunity to be Phoenix. This is us. This is Phoenix.”

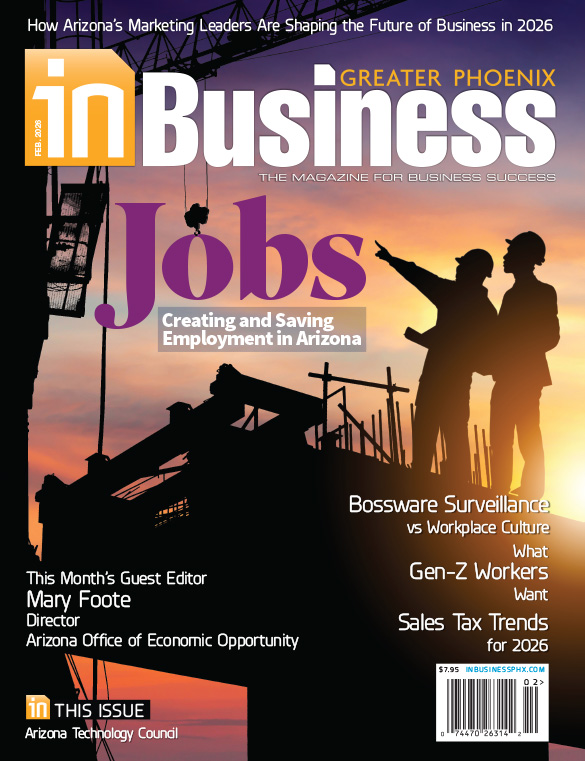

Caption: Honeywell N-95 mask production line in Phoenix will produce 10 million masks each month. The final product comes down a line similar to this one in Rhode Island.